Clean Water Technology Like Ceramic Water Filters are Lightweight, Convenient, and Effective and Can Be Made Using Locally Available Materials and Labor

The clean water technology of ceramic water filters is in common use around the world.

You might be familiar with the clean water technology of small personal-size ceramic water filters that you can buy at a sporting goods store. These filters are often used for camping and such.

In the great outdoors, you may use rainwater or water from a stream as a source of drinking water. But, to be safe and to keep from getting sick from giardia or something else, you can filter the water using clean water technology in the form of a small ceramic filter.

When you think about it, all water filters work the same way. Water that is unsafe to drink is introduced to one side of the filter.

As it works its way through the tiny pores of the filter media (sand, ceramic, cloth, paper, etc.) sediment and pathogens become trapped in the pores.

The water that comes out the other side is then safe to drink.

In ceramic water filter clean water technology, the pore spaces in the porous ceramic filter element are small enough to trap anything bigger than a water molecule.

All ceramic water filters work in the same manner (some personal-size ceramic filters come with a pump that helps force water through the pores).

In addition to the mechanical trapping found in all ceramic water filters, ceramic pot filters are treated with a colloidal silver solution.

The silver acts as a microbicide, killing off any disease-causing bacteria that pass into the filter.

History of Ceramic Pot Filters (Clay Pot Filters)

In developing countries, ceramic pot filters (clay pot filters) have been found to provide excellent clean water technology for household (or point-of-use) water purification.

They were originally developed in Guatemala in 1981 by Dr. Fernando Mazariegos.

Two important organizations in the research, development, promotion, and implementation of clean water technology and specifically, ceramic pot filter programs are Potters for Peace and Resource Development International – Cambodia (RDIC). Both are U.S.-based non-profit organizations working internationally.

When Hurricane Mitch descended upon Central America in 1998, the clean water supply for millions of people was severely affected.

Potters for Peace adopted Dr. Mazariegos’ clay pot filter design and began a Ceramic Filter Production workshop in Nicaragua.

Through the efforts of this workshop (called Filtron), 5000 filters were produced and distributed by various organizations within just 6 months.

Filtron eventually became a worker-owned cooperative and was later incorporated as a private business.

Potters for Peace and RDIC now work around the world to train local partners in the production of ceramic pot filters.

Their model for community development involves training local potters, utilizing local materials and labor, and building a local business which provides profitable and sustainable employment.

Evaluations of ceramic filters in Nicaragua, carried out by Potters for Peace, and the United Nations have shown effectiveness of ceramic pot filters to be near 100% removal of total coliform, fecal coliform, streptococcus, and e. coli.

Clay Pot Filter Construction

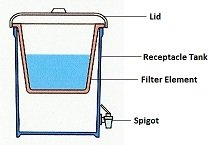

Ceramic pot filters are simple in their design. They can be manufactured locally using local facilities and labor. The entire filter, basically, includes four parts.

The ceramic pot that comprises thefiltering element is made of porous ceramic (similar to a terra cotta flower pot) and is the most important part of the filter.

There is a receptacle tank (often, but not necessarily, a plastic bucket) and the filter fits inside of it.

There is a lid to cover the filter and keep out dirt and contamination, and there is a spigot installed at the base of the receptacle through which filtered water is removed for use.

Operation and maintenance are simple and straightforward, making these filters ideal for point-of-use water treatment.

Advantages and Disadvantages of Ceramic Pot Filters

Advantages

* Ceramic filters are small and lightweight enough so a child can carry them.

* Filtration is extremely effective (up to 100%) at removing pathogens and sediment.

* Silver colloid coating ensures disinfection of drinking water. No further disinfection is needed.

* Ceramic filters can be produced locally, using local resources and labor.

* They are relatively inexpensive ($15-$25).

* Ceramic filters are aesthetically desirable and able to be decorated for inclusion in a household.

Disadvantages

* Ceramic filters have a fairly slow flow rate (1 – 3 liters per hour).

* Ceramic is fragile and can easily be cracked during handling.

* Cracks may be undetectable, but still affect filtering capability.

* Turbid water can plug up pores in ceramic.

* Cleaning results in removal of silver colloid and ceramic layers, and overtime, filter will need to be replaced.

* Good quality control is required in production of filters.

Return "Home" from "Clean Water Technology"